2010 Front Engine Dragster Week 2011 01 11

REMEMBER TO CLICK PICTURES FOR MORE DETAIL / LARGER PICTURE

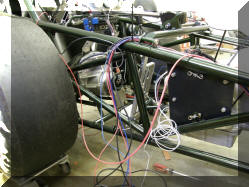

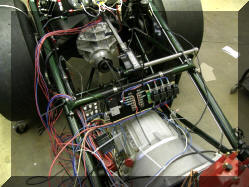

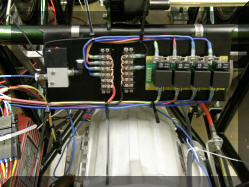

Ok, the dragster wiring continues

It was mentioned to me that there was some confusion as to why the wiring is taking so long because, after all, it is a dragster and how much wiring could there be?

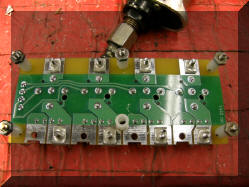

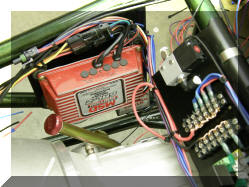

Well there are a number of things that have to be wired; fuel pump, water pump, radiator fan, starter (these are all high current draw systems and cannot just be wired with a switch, they require a relay in the circuit to carry the current required to run these items), coil, distributor, data logger (this is a whole wiring circuit all by itself), gauges, MSD box, RPM Trigger (the tach does not have a shift light so a RPM trigger is needed to run the shift light), neutral safety, air shift (electrical circuit), transmission brake, shift light, low oil pressure light, and last but not lest the tail light.

All components have been wired with weather pack connectors so any one component can be removed and replaced without having to cut wires.

The whole harness is being wired so that it is removable so that when the blower engine is install this harness can be removed as one piece and a new harness install for the needs of the blower engine (Magneto and transformer (Matt I used the right terms just for you). If the need arose to remove the blower engine this one will be able to reinstalled with this harness (back up engine)

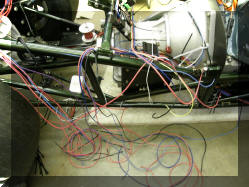

The rat’s nest of wires is slowly being reduced and made “neat”

Tom Deyle has taken on the task of modifying the air scoop to function with a single 4 barrel carburetor vs the dual four barrel carburetors it was original set up for. In addition he is creating a way to mount the scoop to the carburetor

The scoop is also being modified to hold the shift light and low oil pressure light. Matt’s shop did the machine work on the scoop to have the lights poke through the rear of the scoop, Don Goodman modified the light brackets so they would be at the correct height to line up with the holes (this may sound like a simple task, but the lights have to be level and straight. Any carpenter will tell you one of the hardest things to do is to make a well fit square box, it may look simple, but it is hard to do. (I’m gun shy after blowing up the engine in the Firebird with what is thought to have been a low oil pressure problem).

I picked the air scoop up at the last Rochester Street Rod swap meet ( I have heard rumors that there will be another one this summer, there was lots of good stuff at the last one, be sure to put it on your calendar for a do not miss event)