Powder Coat Part 2: What can you expect?

Click image to see larger picture

It is very convenient. Blast a part, heat it to out gas, let it cool, put the powder on, and heat again, let it cool again. The part is now fully cured and you can bolt it on without fear of harming the coating. Note that there is none of the waiting like with paint that can take 48 hours to a week to fully cure.

Powder coat is not as finicky as paint, and as I have pointed out above, it does not take as much skill as paint. However, powder coat will never take the place of paint. By that I mean you can get a very good finish with powder but it will never approach the glass finish you can get with paint. On the other hand it is much more durable than paint. It is essentially plastic that you melt onto a surface of the piece of metal you are working on. It is very difficult to chip, resists gas, alcohol, and holds up well to abuse.

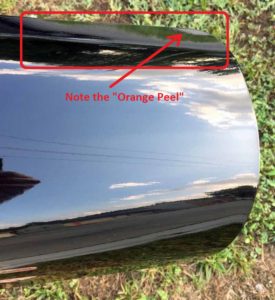

Vanity prevented me from using a piece that I had powder coated so I pirated an image from fee-bay that was being used to sell pound quantities of glass black. I picked this picture because the seller obviously wanted to depict his powder in the best light, but it still shows the only drawback that I know of with powder coat. In general the piece looks darn nice.

If you look at the top right edge you will see some “orange peel.” You sometimes get this effect when you powder coat. If you accept that limitation of powder, you will love it. With paint, you can color sand and then clear coat and wet sand and buff it to a glass finish. With powder coat, you could sand the powder coated surface and then re-coat the piece again; there is no option to wet sand and polish the final surface. The side effect of re-coating is each time you do it over again you build up thickness

If you look at the top right edge you will see some “orange peel.” You sometimes get this effect when you powder coat. If you accept that limitation of powder, you will love it. With paint, you can color sand and then clear coat and wet sand and buff it to a glass finish. With powder coat, you could sand the powder coated surface and then re-coat the piece again; there is no option to wet sand and polish the final surface. The side effect of re-coating is each time you do it over again you build up thickness

Ok, so now let’s talk some about the requirements of the powder coat process.

Probably the most basic requirement and one of the most crucial steps in producing a nice durable finish is: